Spray valve has been said in front of the fan spray valve, today to talk about the circular spray valve, using the same material and technology produced by the spray valve, only in the atomization interface is different, one is round, the other is fan-shaped, the atomization effect will show different effects, fan fan circumference, small circle, atomization intensive, the difference is this.

Fan spray valve parameters

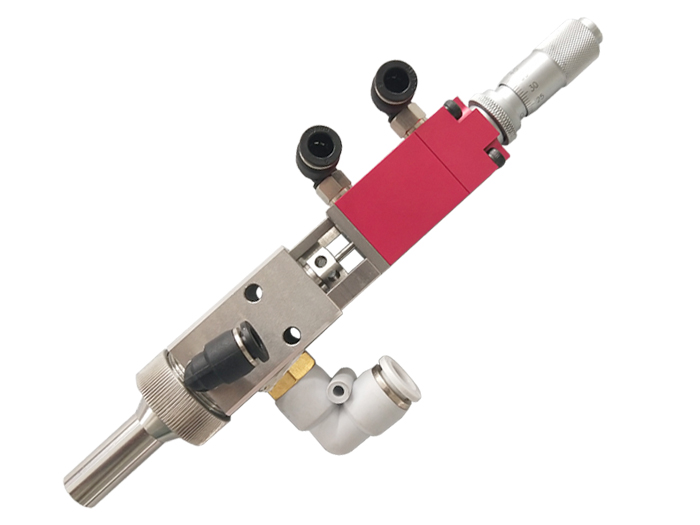

Product Name: round micrometer spray valve product model: ZZ-SX-65S

Product type: high frequency spray (round) pneumatic form: double acting cylinder

Main material: 304 stainless steel + aluminum alloy spray effect: fine water atomization (anhydrous particle)

Operating viscosity: 1 ~ 5000cps; weight: 250g

Feeding pressure: < 300kg feeding size: 1 / 8 "NPT (f)

Operation rate: 600 / min; air source: 0.1 ~ 7kgf / cm

Size of dispensing valve: (d) 21 * (H) 204.2 applicable glue: paint, ink, alcohol

The characteristics of the circular spray valve.

1. It is easy to install and use, and can be used on manual or automatic machines.

2. The continuous atomization effect is good, and the fine water atomization can be realized. The fog like effect is consistent with that of ordinary fog days.

3, spray uniformity, in each product details are uniform, plane thickness consistency.

4. With micrometer adjustment device, the atomizing distance can be adjusted to achieve precise atomization spray effect.

5. It is made of stainless steel and aluminum alloy. The built-in piston is made of silica gel. It has good sealing effect and long service life.

6. Wear and corrosion resistance.

The circular spray valve is equipped with a micrometer adjustment function, which can reduce the spray range. Some thicker paint layers can use circular spray valves. Each product is very targeted, so that it can meet the production needs of customers. Otherwise, it will not produce various types of spray valves, especially for some highly demanding products, which can meet the requirements of better use.