Do you know how to use double liquid ab glue? Which kind of rubber valve can satisfy the requirement of double liquid glue? What kind of dynamic mixing valve can be used for low, medium and high viscosity glue and different proportion glue? Let Xiaobian tell you how to use the double liquid backdraft valve and choose the dispensing valve?

Parameters of dynamic mixing valve:

Model: 32LAB

Applicable Viscosity: 1-1 million CPS

Dispensing speed: <600/mm

Feed pressure: <10kg

Feed Size: 1/4npt"or 1/8npt"

Feed Size: 1/4npt"or 1/8npt"

Flow regulation: Yes.

Shape: Square

Minimum vomiting volume: 0.1mm

Rubber outlet: trumpet and chuck

Viscosity for general rubber valves

This is the basic parameters of the dynamic mixing valve. This kind of rubber valve can be more viscous than the general double-liquid backdraft valve. The general mixing dispensing valve can be applied to 200,000 viscous. It is more comfortable to use high viscous or dynamic mixing. Without much change, high viscous glue can be obtained. Normally the double-liquid backdraft valve is not. Have the effect.

Applicable Ratio of Dynamic Mixing Valve

Dynamic mixing valves can be used in the proportion of 1:1, 2:1, 3:1, 4:1, 5:1 to 10:1. The performance of dynamic mixing valves is the most stable. After 4, customization is needed, and the effect may be unstable. These technical problems, dual-liquid backdraft valves come out of the market soon, can be used. The production of 10:1 is already very strong. However, more than 5:1 need to be customized, but also need to understand the nature of glue, whether it can be used, to produce a dynamic mixing valve.

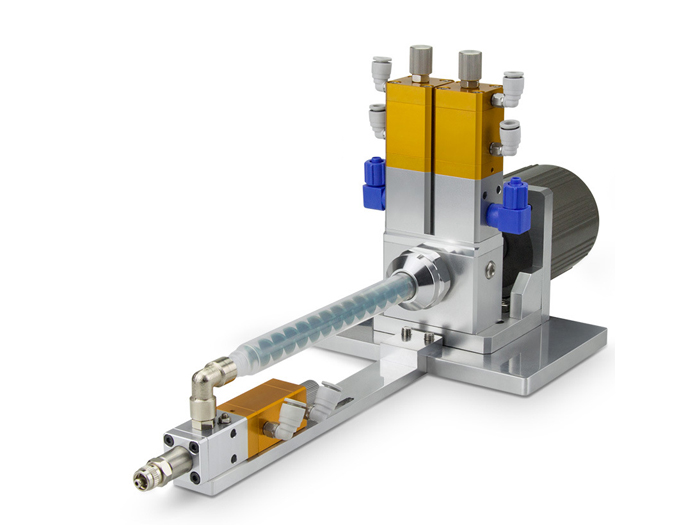

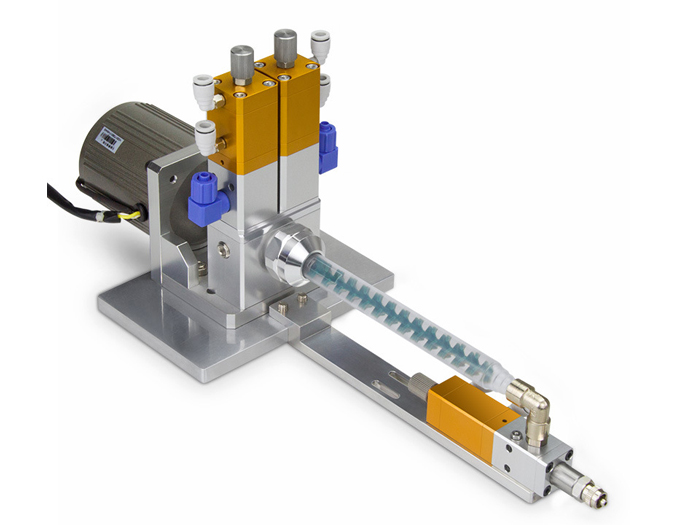

Mixing valve structure

Mixed dispensing valves need to be equipped with mixing pipes and motors to drive the fan blades, and then mix glue to achieve the effect of mixing, but also to promote glue flow. According to different dispensing industries, dispensing production can be accelerated. The main role of dynamic mixing valves is glue mixing degree.