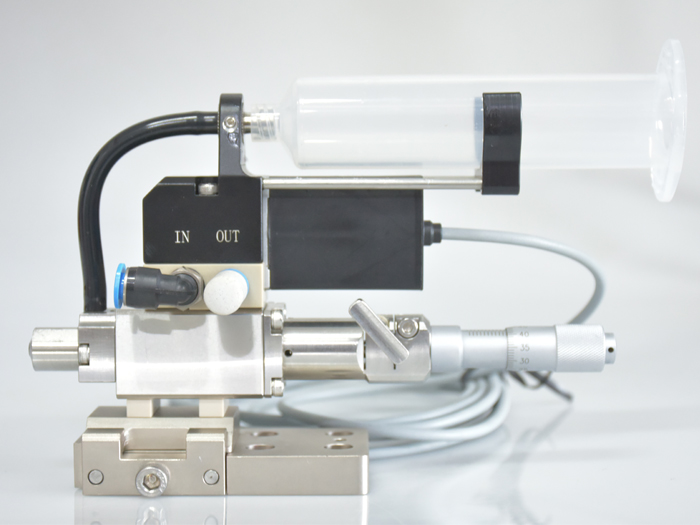

Piezoelectric spray valve is generally the top type of dispensing valve. It uses the way of impact pin to dispense glue. It can eject glue in the way of spraying, so that glue can be ejected at a fast speed. There is no need to configure a needle at the rubber outlet. It can do 800 times of impact pin in a minute. It is a hot product. It dispenses glue for some medium and low viscosity glue, with excellent quality.

Injection valve features

1. Break the traditional dispensing mode, use non-contact dispensing, dispensing valve can still dispensing without touching the product.

2. Three axis to two axis, Z axis does not need to move, also can carry out product dispensing.

3. The dispensing accuracy will be significantly improved, and 0.3mm linear dispensing can be carried out.

4. Controller imported from Germany, colloid is a domestic brand, the core function of the product is the same, and the price is half cheaper.

5. No sawtooth, no wave, no splash, no nozzle.

Parameters of piezoelectric injection valve

Model: zz-px-6xt voltage: 24V

Dispensing valve Name: piezoelectric spraying valve working mode: spraying dispensing

Operating viscosity: 5000cps injection speed: 800 / min

Applicable syringe: 55ml / 30ml control mode: exclusive controller

Dispensing diameter: Min 0.25mm dispensing line width: Min 0.26mm

Applicable glue type: UV glue, bottom filling glue, paint, ink, red glue, hot melt glue

Difference between voltage and air pressure dispensing valve

There is a very big difference between dispensing valves. Voltage access is the use of other accessories, which will improve the dispensing performance of the dispensing valve. For example, piezoelectric injection valve uses voltage to drive the solenoid valve, and then turns to the screw, so as to spray out the glue in a high-pressure state, so as to achieve the dispensing effect. The air pressure needs to be positioned by the dispensing needle. According to the size of the needle, I think Precise piezoelectric injection valve for rubber discharge

Piezoelectric spray valve is generally the top type of dispensing valve. It uses the way of impact pin to dispense glue. It can eject glue in the way of spraying, so that glue can be ejected at a fast speed. There is no need to configure a needle at the rubber outlet. It can do 800 times of impact pin in a minute. It is a hot product. It dispenses glue for some medium and low viscosity glue, with excellent quality.

Injection valve features

1. Break the traditional dispensing mode, use non-contact dispensing, dispensing valve can still dispensing without touching the product.

2. Three axis to two axis, Z axis does not need to move, also can carry out product dispensing.

3. The dispensing accuracy will be significantly improved, and 0.3mm linear dispensing can be carried out.

4. Controller imported from Germany, colloid is a domestic brand, the core function of the product is the same, and the price is half cheaper.

5. No sawtooth, no wave, no splash, no nozzle.

Parameters of piezoelectric injection valve

Model: zz-px-6xt voltage: 24V

Dispensing valve Name: piezoelectric spraying valve working mode: spraying dispensing

Operating viscosity: 5000cps injection speed: 800 / min

Applicable syringe: 55ml / 30ml control mode: exclusive controller

Dispensing diameter: Min 0.25mm dispensing line width: Min 0.26mm

Applicable glue type: UV glue, bottom filling glue, paint, ink, red glue, hot melt glue

Difference between voltage and air pressure dispensing valve

There is a very big difference between dispensing valves. Voltage access is the use of other accessories, which will improve the dispensing performance of the dispensing valve. For example, piezoelectric injection valve uses voltage to drive the solenoid valve, and then turns to the screw, so as to spray out the glue in a high-pressure state, so as to achieve the dispensing effect. The air pressure needs to be positioned by the dispensing needle. According to the size of the needle, I think Glue out accuracy.