The problem of spray valve usually occurs after the closure of the glue valve. The 95% rule of the problem is caused by the diameter of the needle. The small needle will affect the flow and pressure of the liquid and cause back pressure, which will cause leakage shortly after the glue valve is closed. When the spray valve is used, the small needle will also affect the discharge of bubbles. This problem is solved by replacing the larger needle. The back pressure produced by the tapered needle is the smallest and the liquid flow is the smoothest. When the glue valve is closed, air in the liquid will leak. It is best to remove air from the liquid in advance, or use glue that is not easy to contain bubbles, or centrifugal and defoaming the glue before use.

The inconsistency of glue delivery is mainly caused by the unstable air pressure and insufficient pressure in the pressure cylinder or storage liquid cylinder. The inlet pressure regulator should be set at 10-15 pounds/square inch lower than the factory minimum pressure. The pressure used in the pressure cylinder should be adjusted to the middle of the pressure regulator. The low pressure part of the pressure gauge should be avoided. The control pressure of the glue valve should be at least 60 pounds/square inch to ensure stable glue output. Finally, check the glue output time. If it is less than 15/1000 seconds, the glue output will be unstable, and the glue output time will become more stable until it reaches 30/1000 seconds.

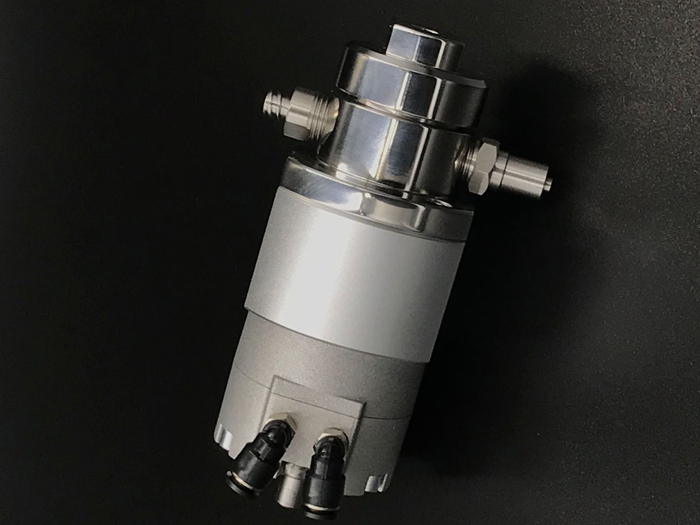

Rotary spray valve

3. The flow rate is too slow. If the flow rate is too slow, the pipeline should be changed from 1 / 4 "to 3 / 8". If not necessary, the pipe should be as short as possible.

4. If the opening time of the valve is too short, the high fluid pressure caused by bubbles in the fluid may cause air infiltration into the liquid. The solution is to reduce the fluid pressure and use a tapered tip.

Spray out